2024-11-23

classification:Company News

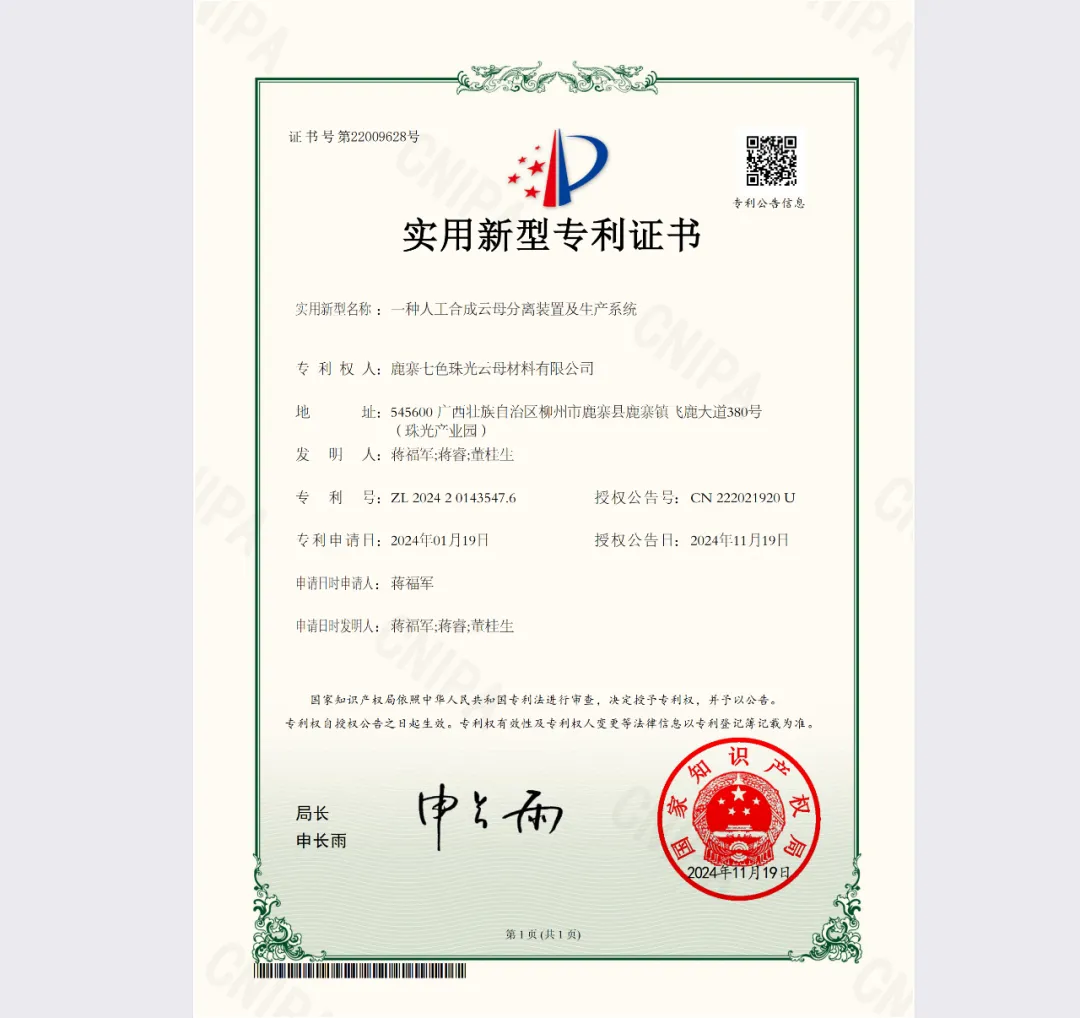

Luzhai Chesir Pearlescent Mica Material Co., Ltd., a subsidiary of Global New Material International Holding, recently obtained the utility model patent of “a synthetic mica separation device” authorized by the State Intellectual Property Office. This breakthrough innovation has achieved remarkable results in optimizing the production process, improving resources utilization and reducing production costs, providing solid technical support to reduce cost and enhance efficiency, and demonstrating our determination and strength in promoting intelligent and green development of mica industry.

All-round cost reduction: a new benchmark for cost optimization

The application of the new patent fundamentally solved the problem of wasting of resources and cumbersome process in the production process of traditional synthetic mica, and significantly reduced the operating costs by comprehensively optimizing the production process:

- Lowerthe waste of raw materials: through the application of the precise separation device, the loss of refractory materials caused by the demolition of the furnace body waseffectively reduced, and the utilization of raw materials was significantly improved.

- Reduce labor costs: The fully automated device took over manual operation, greatly reducing manual intervention and requiring lesspersonnel training and management.

- Improve production efficiency: The intelligent system spedup the optimization of the production cycle, avoidedthe extra consumption of resources and energy caused by the lengthy process, and created higher productivity and economic benefits.

This patented technology set a new benchmark in resources utilization and cost control, and significantly enhanced the ability to withstand pressure in response to market fluctuations.

Unlock long-term profitability from green manufacturing

The new patent not only significantly reduced the production cost, but also continued to unlock the long-term profitability of green manufacturing through the wide application of environmental protection technology:

- Maximize energy efficiency: Optimize energyutilizationin the production process, significantly reduce energy waste, and save long-term operating costs.

- Reduce spending on secondary treating: The reduction in the loss of refractory materialseliminatedthe need to pay high costs for the disposal of waste materials, while optimizing the overall material recovery rate.

- Prolong equipment lifecycle: Improveddevice reduced wear and tear in equipment operation, enhanced equipment stability and reduced maintenance.

Through the combination of green technology and cost control, Chesir not only achieved efficient production, but also continued to improve profitability, providing investors with a long-term stable return.

Efficiency enhancement and empowerment: value enhancement of the whole process

The innovative design of the patent also helped us to improve comprehensive benefits while producing efficiently:

- Reduce capacity lossdue to redundant process in traditional process and unlock more capacity potentials;

- Optimize the allocation of human resourcesso that limited personnel input can create greater value;

- Improve the stability of product quality, reduce economic loss caused by defectivepercentage, and further enhance the market competitiveness.

This result has comprehensively improved the operational efficiency from the production end to the market end, and laid a solid foundation for building up our global competitiveness.

Build a technology moat to win market confidence

The successful application of the new patent brought not only another breakthrough to reduce costs and increase efficiency, but also showed the comprehensive strength of Luzhai Chesir in technological innovation and industrial upgrading. For investors, cost optimization benefits brought by this patent will significantly enhance the ability to withstand market risk and generate a bigger room for profit growth.